Amber-ETM Products

Hathaway’s Amber-E™ polysilazanes can be pyrolyzed to high-quality, industrial ceramics for markets, including military, aviation/aerospace, medical, communications, transportation, and a host of other uses. Applications include ceramic MEMS, ceramic matrix composites (CMCs), metal matrix composites (MMCs), ceramic joining, SiC/Si3N4 coatings for C/C composites, and ceramic nanocomposites.

Hathaway’s Amber-E™ polysilazanes were invented by Americans in the USA by an American company.

These remarkable materials can be cast, molded, painted, troweled, sprayed, blended, or injected. They can be plasticized and machined like ordinary plastics. They can infiltrate fibers, woven materials, granular materials ranging from crushed rock to nanoscale platelets.

Classes of Products

Pre-ceramic and Composite Resins

Amber-E™ VP000: Heat-Curable Ceramic Precursor Prepreg Resin

Amber-E™ VP000 Prepreg Polysilazane is a soft solid that deforms under pressure and can be readily thermo-set to a hard, rigid solid by heating to 180°C‒200°C. Alternatively, Amber-E™ VP000 can be cured at lower temperatures by adding a small quantity of a free radical initiator. The resulting solid can then be pyrolyzed to either silicon carbide or silicon nitride by heating to 1,000°C. Amber-E™ VP000 is a firm solid when cooled, is soft and tacky at room temperature, and becomes a viscous liquid when warmed.

Major Application:

CMC Prepregs

Amber-E™ VS000: Melt/Fusible Ceramic Precursor SOLID Polysilazane

Amber-E™ VS000 is a solid polysilazane that when heated becomes a free-flowing liquid. Amber-E™ VS000 can be melted- or solvent-spun into fibers. Fibers spun from Amber-E™ VS000 are readily shape stabilized prior to pyrolysis by various methods, including radical initiated or photolytic processes. The resulting fibers can then be pyrolyzed to silicon carbide, silicon nitride, silicon carbonitride, or silicon carboxynitride by heating to 1,000°C. The final ceramic phase is dependent upon the pyrolysis atmosphere. The ceramic yield as measured by thermal gravimetric analysis (TGA) is 84% in a nitrogen atmosphere.

Major Application:

Ceramic matrix composites, metal matrix composites, ceramic fibers, and ceramic coatings.

Amber-E™ VPSZ-20: Heat-Curable Ceramic Precursor

Amber-E™ VPSZ-20 is a liquid polysilazane that is readily thermo-set to a solid by heating to 180°C‒200°C. Alternatively, Amber-E™ VPSZ-20 can be cured at lower temperatures by adding a small quantity of a free radical initiator. The resulting solid can then be pyrolyzed to either silicon carbide or silicon nitride by heating to 1,000°C.

Amber-E™ VHC000: Heat-Curable Coating Resin

Amber-E™ VHC000 is a pale yellow, low viscosity liquid polysilazane-based coating resin that is specially designed for use in the formulation of heat-curable ceramic coatings. Amber-E™ VHC000 is supplied as a low viscosity liquid 100% "solids", and it rapidly solidifies upon heating to 200°C‒250°C. Solidification can be achieved at lower temperatures with the addition of a free radical initiator such as dicumyl peroxide.

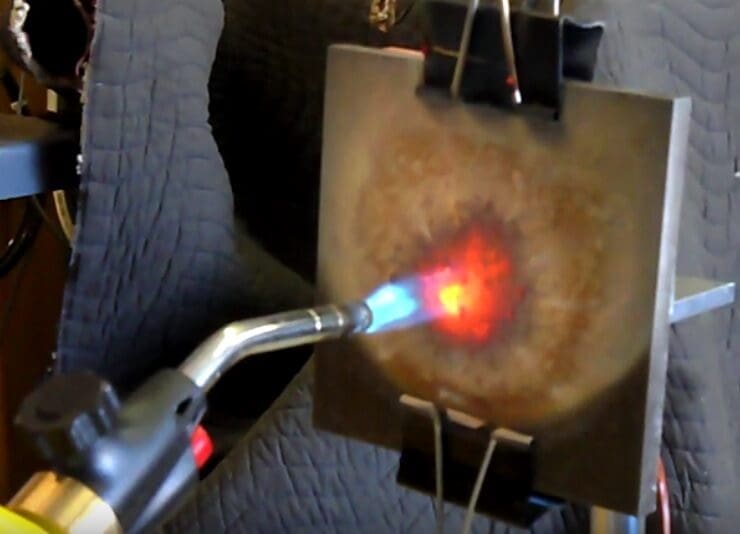

Amber-E™ VHC000 can be blended with a variety of pigments, such as metal powders (zinc, aluminum, stainless steel), ceramic powders (silicon carbide, aluminum oxide, silicon nitride), etc. Such compositions can be formulated with or without solvent and can be applied by dipping, spraying, or brushing onto a variety of substrates—metal, glass, and ceramics. For ultrahigh-temperature formulations, the coated part is then heated to at least 454°C to promote conversion of the polymer to ceramic. Depending on the exact formulation, coating operating temperatures of 900°C or above can be achieved.

Major Application:

High Temperature Coatings and Thermally Stable Corrosion Coatings

Intumescent Materials

Amber-E™ IC000: Optically-clear, intumescent plastic window panels.

Amber-E™ IC000: Optically-clear, intumescent plastic window panels. Amber-E™ IC000 is a unique intumescent material with high flame resistance, low thermal conductivity, and minimal off-gassing.

Development is presently underway to apply the intumescent protective barrier material as a paint-on, spray-on, or trowel-on coating, making it amenable to coating structural members of buildings, protective coatings for aircraft cabins, automobiles, maritime engine compartments, NASCAR driver compartments, and a host of other applications to which protection from heat and flame is a matter of life and death.

Amber-E™ IPR00: Intumescent powdered resin < 200 mesh. Same fine formulation as Amber-E™ IC000, but in powdered form suitable for formulation into coatings, paints, composites, and fillers.

Specialty Materials

Specialty Materials

- Amber-E™ HMDS: Pure Synthetic Grade Hexamethyldisilazane

- Amber-E™ TDMS: Pure Synthetic Grade Tetramethyldisilazane

- Amber-E™ VSP00 (Powder)*: Polysilazane Powdered Resin < 200 Mesh

- Amber-E™ MR2000: Mold Release

- Amber-E™ Borosiloxane: Low viscosity borosiloxane liquid polymer hat can be thermo-set to a solid by heating to 250°C without a catalyst. Upon heating to higher temperatures, the resin converts to a composition that is a borosilicate glass

Composite & Hybridzing Resins

Composite & Hybridizing Resins

Amber-E™ D8500: Hybridizing/composite resin. Whether the topic is intumescent materials, durable wear surfaces, flameproof composites, cementitious building materials, regolith-binders for lunar construction, or radar domes, Hathaway’s Amber-E™ D8500 is ready to perform. Its unique bonding and adhesive properties, coupled with its renowned thermal stability, moisture and corrosion resistance, UV stability, and light weight make it ideally suited for the most advanced composites and hybrid formulations. And because polysilazane’s properties can be incorporated into hybrids, ordinary polymer systems, can demonstrate enhanced performance and remain economically attractive.

Amber-E™ D6600: Hybridizing/composite resin. Fewer dimethyl groups—lower cost.

Amber-E™ D3300: Hybridizing/composite resin. Amber-E™ D3300` is a coating workhorse, suitable as the base carrier for thousands of coating formulations, ranging from automotive appearance finishes to anti-graffiti coatings. It is suitable for household applications, including protecting metal finishes, tools, plumbing fixtures, lawnmowers and garden tools, stove and refrigerators, etc. Amber-E™ D3300 also addresses a range of maritime applications, ranging from antifouling, salt-spray corrosion, wood finishes, UV protection, and metal surfaces, including steel, aluminum, brass, and copper.

Amber-E™ D33MF: Clear coat. Rapid self-cure*

Amber-E™ D33MS: Clear coat. Slow self-cure*

Amber-E™ D33MA: “Goldilocks” Just-right cure (adjustable)*

Amber-E™ D33M Silazane Self-Cure* is a consumer grade, moisture cured wipe-on coating for home, shop, auto, lawn and garden, and other applications. Packaged as single-use wipes in sealed foil envelopes for small jobs, this product provides the same properties as the commercial grade Amber-E™ D3300 sold to coating formulators.

*Products currently under development. May not be commercially available. Please contact us for more information.